CR700 5987 views

Our new CR700 was developed to further optimize cranes based on the concepts of Flexible, Easy, Sustainable.

Yaskawa can now deliver the most ideal “answers” for various tasks related to the operation of cranes, including brake sequences that have evolved from the technologies we have developed to date.

By revolutionizing your facilities and machines, the CR700 will increase productivity, save energy efficiently, reduce total costs, with enhanced environmental compatibilities.

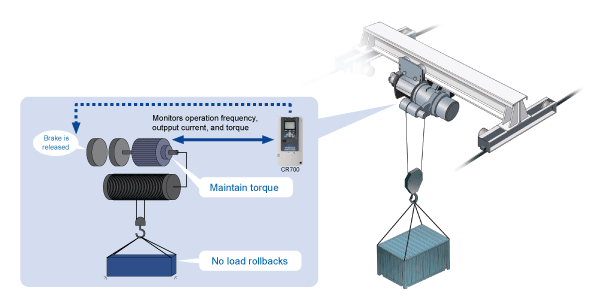

The break release command is judged and output in relation to the operation frequency of the drive, output current, and amount of torque. Brakes are released and applied while ensuring enough torque to maintain the load during starts and stops to prevent load rollback.

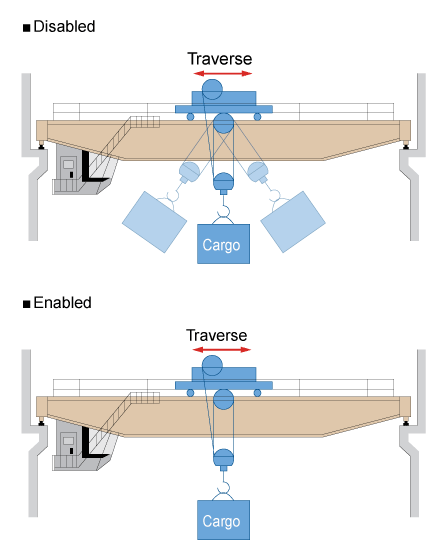

Cargo swing during traverse motion can be reduced with the built-in Anti-Sway Control. This enables cargo to be lowered without any swing, which reduces takt times.

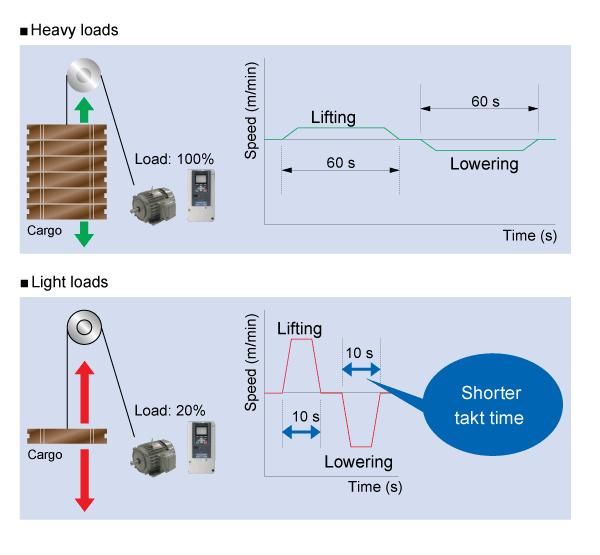

With this light-load, high-speed function, our drive operates at optimal speed in accordance with the load.

High-speed operation can be performed when handling light loads. This shortens the takt times when using long lifting cranes, such as those used in constructions.

One drive can switch between and control motors with three axes for lifting/lowering, travelling, and transverse operations. Our drive can support individual brake sequences for each motor, so downtime during a drive failure can also be reduced as a result of the ability of drives to act as substitutes for other motors. Traditionally, one drive was needed for each motor. However, one drive can switch between motors to reduce the number of drives needed.

With performance life monitors, the approximate maintenance period of parts can be output as an alarm signal to notify users in advance.

In addition, you can monitor the deterioration status of the parts which can help you to make a maintenance plan easier.

The monitor keeps a count of the number of brake commands. This information is helpful in determining brake maintenance schedules for inspecting system and replacing parts.

Products & Support