When producing a large number of products with the same models and specifications, such as home appliances, we can combine industrial robots and servomotors to produce them on automated production lines. However, as the product life cycle becomes shorter and mass customization is required in recent years, it is necessary to prepare parts and production facilities according to the specifications of each customer, especially when products are manufactured differently. In other words, at the manufacturing site, workers are required to manually arrange parts and change the grippers.

However, in this case, it takes time to change the setup and you need to stop the line every time. In the manufacturing industry, if you don’t produce the same model at a certain volume, you won’t be productive. It is also a great challenge for the factory automation industry to flexibly implement set-up in a short time and labor-saving manner to meet individual customer needs.

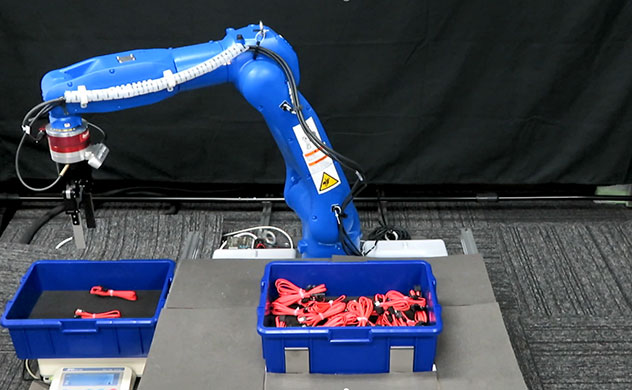

These problems can be solved by adding redundancy to automated production lines using industrial robots, etc. and managing them using digital data. This will enable automatic setup changes without manual intervention, and enable the realization of high variety and variable quantity from a minimum of single unit. Our company’s factory that produce servomotors have had to produce about 20 units of the same models and specifications, but with thorough automation of set-up and utilization of data, we are now able to flexibly produce a single servomotor even if it goes into the middle of production schedules.

Other solutions

-

Production

-

Quality

-

Maintenance

Accuracy improvement

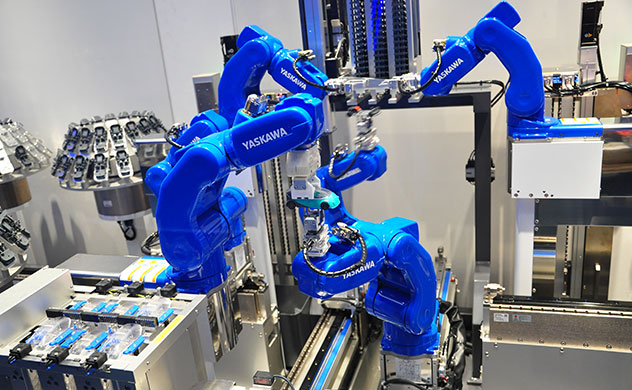

Accuracy Improvement of Defect Cause Analysis < Yaskawa Case >

By “visualizing” the operation status of equipment/devices with Yaskawa Cockpit, it is possible to identify the root cause by comparing the normal value and abnormal value of the data in the factor analysis for defects in production.

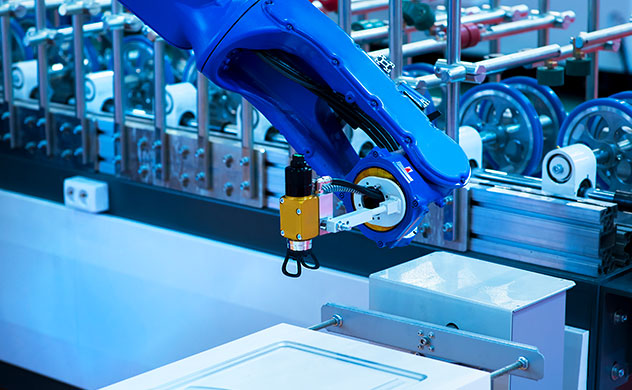

Quality inspection

Automated Product Quality Assessment with AI

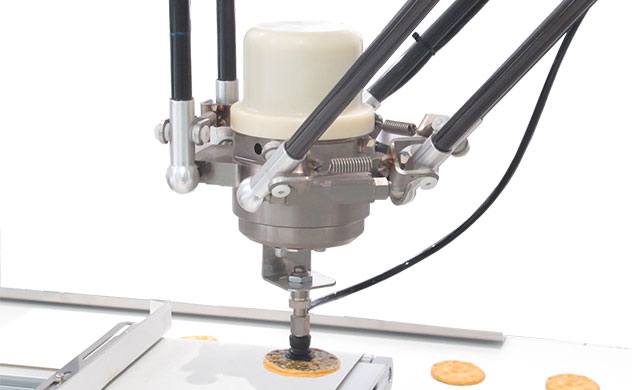

When the quality inspection process is labor-saving, the use of an image judgement service that utilizes AI technology such as deep learning makes it possible to automatically determine complex No Good patterns with the same level of accuracy as humans.

Israel

Israel Thailand

Thailand Japan

Japan Singapore

Singapore China

China Korea

Korea Taiwan

Taiwan Vietnam

Vietnam Germany

Germany United States

United States