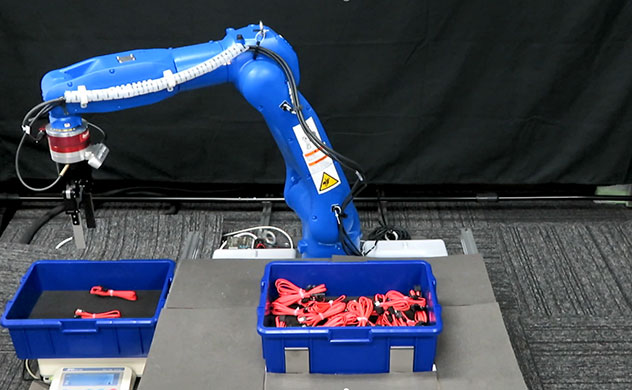

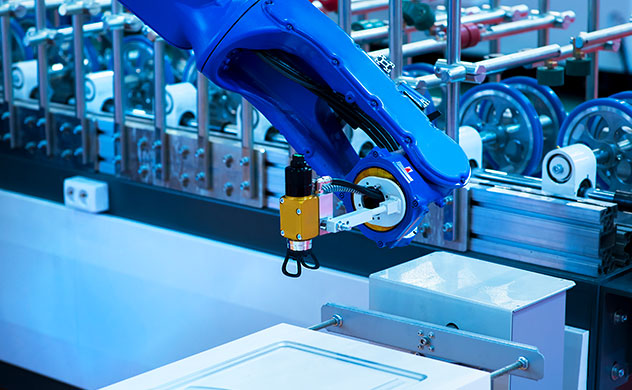

If an industrial robot stops unexpectedly on a factory line, the robot in the next step in the production sequence will also be unable to proceed. If this happens, the entire line stop when one robot stops. This is because when the robot is controlled in one direction by a controller such as a programmable logic controller (PLC), the robot can only perform the operations indicated in the order given. In order for robots to work autonomously and cooperatively with other robots, it is necessary for them to have the ability to think and judge for themselves. This type of manufacturing is called “autonomous decentralized manufacturing. “

By absorbing data such as torque value, vibration value, or temperature from the servomotor into the controller, the autonomy aspect of the robot is enhanced, and the robot can determine how to move if any other robot stops moving in the previous order.

Other solutions

-

Production

-

Quality

-

Maintenance

Accuracy improvement

Accuracy Improvement of Defect Cause Analysis < Yaskawa Case >

By “visualizing” the operation status of equipment/devices with Yaskawa Cockpit, it is possible to identify the root cause by comparing the normal value and abnormal value of the data in the factor analysis for defects in production.

Quality inspection

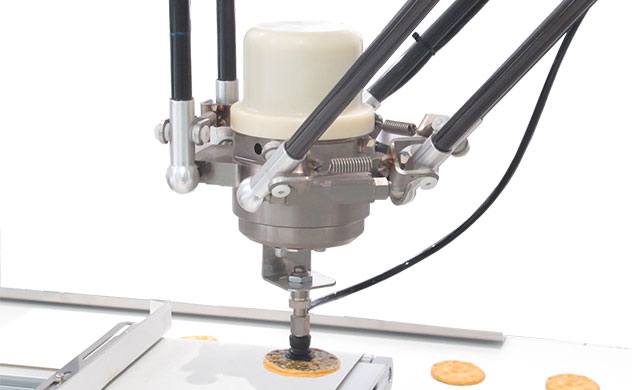

Automated Product Quality Assessment with AI

When the quality inspection process is labor-saving, the use of an image judgement service that utilizes AI technology such as deep learning makes it possible to automatically determine complex No Good patterns with the same level of accuracy as humans.

Israel

Israel Thailand

Thailand Japan

Japan Singapore

Singapore China

China Korea

Korea Taiwan

Taiwan Vietnam

Vietnam Germany

Germany United States

United States