Varispeed G7 - Advanced Vector Control

Varispeed G7 14470 views

In consideration of the different usage environments throughout the world, this inverter boasts high levels of both performance and operability, and stands ready to meet the most stringent technological demands. For the first time, 3-level control has been incorporated in 400-V class, general-purpose inverters to solve the problem of micro-surge voltages. It can be used in existing motors.

Features of the 3-level control method

The first 400V class general-purpose inverter in the world to use the 3-level control method, to approach sine wave output voltage. It provides the solution to problems like motor insulation damage to surge voltage, and electrolytic corrosion of motor bearings due to shaft voltage. Existing general-purpose motors can be used even without surge suppression filters. The noise and leakage current are greatly reduced (halved in in-house comparison).

Low surge voltage

Suppresses surge voltage to the motor, eliminating the need for surge voltage protection for the motor.

Low electrical noise

Significantly reduces conduction (power supply) noise and radiated noise caused by inverter drives, minimizing effects on peripheral devices.

Low acoustic noise

Provides low acoustic noise, difficult to achieve with conventional designs.

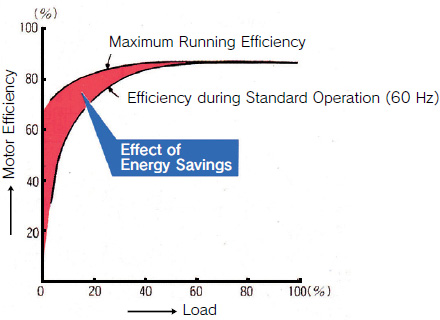

Extensive energy-saving control

The energy-saving control approaches the maximum efficiency. High-efficient, energy-saving operations are achieved for any application either in vector control or V/f control.

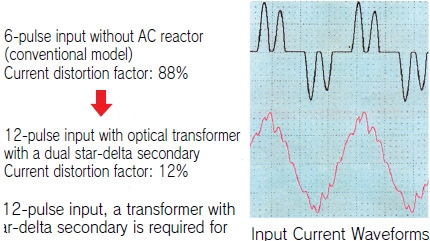

Countermeasures to minimize harmonics current

All models of 18.5 kW or more come equipped with DC reactors to improve the power factor, and support 12-pulse input (Note).

- Note : For 12-pulse input, a transformer with a star-delta secondary is required for the input power supply.

Supporting global field networks

All models are fully compliant with RS-422/485 (MEMOBUS/Modbus protocol) standards. The networks are available by using communications option cards. Now you can connect to hosts and PLC, implement centralized management of production equipment and reduce wiring easily.

- ∗1 : DeviceNet is a registered trademark of Open DeviceNet Vendors Association.

- ∗2 : LONWORKS is a registered trademark of Echelon Corp.

Digital operator with support for seven languages

The LCD panel digital operator that is included as standard equipment supports seven languages: Japanese (katakana), English, German, French, Italian, Spanish, and Portuguese.

Global standards

Certification received: UL/cUL, CE marking, and KC marking

Various power supplies

Meets a variety of world power supply

- Three-phase 200 V series (200 to 240 V)

- Three-phase 400 V series (380 to 480 V)

DC power supplies such as common converters are also available.

Global service

Our service networks cover U.S.A., Europe, China, South East Asia, and other parts of the world, and provide support for your business abroad.

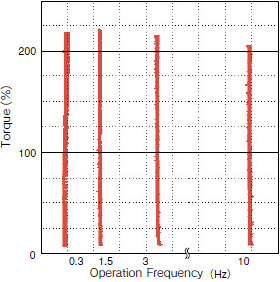

Outstanding torque characteristics

- The new observer (patent pending) improves torque characteristics (150%/0.3 Hz for open loop vector control 2) to provide high power for every machine. With PG, more than 150% high-torque operation is possible even at zero speed.

-

High torque from 1/200 speed

(Dynamic auto-tuning, open loop vector control)

[speed control range 1:200 with PG 1:1000]

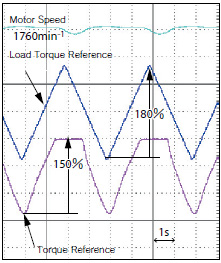

Accurate torque control

- The precision torque limit function allows accurate control of the output torque, protecting your machines from sudden load fluctuations.

Torque Control (Torque limit set at 150%)

Proven responsiveness

- The model tracking control assures fast response even without PG (doubled in in-house comparison).

- With a PG you can make use of our unique high-speed current vector control, rapidly responses speed reference changes (speed response 40 Hz/motor unit). Speed keeps constant even if load fluctuates.

Quick response to reference changes

(Speed reference step response)

Handles sudden load fluctuations

(Speed recovery characteristics upon load surges)

High-speed search (patent pending)

- The high-speed search function reduces the recovery time after momentary power loss (halved in in-house comparison).

- Recovery is possible regardless of direction of rotation.

Quick, shockless start

(Continued operation after momentary power loss)

Simple auto-tuning

- In addition to conventional dynamic auto-tuning, a new static auto-tuning is available to draw out peak performance from the motors of the world.

Safety and protection functions

- High-speed, high-precision current control functions support continuous operation by suppressing overcurrent trips, restart after momentary power loss, stall prevention and fault retry.

- The PTC thermistor in the motor helps protect it against overheating.

Simple operation

- The 5-line LCD display operator makes it simple to check necessary information.

And the copy function simplifies constant upload and download. - Easy to setup with the quick program mode.

- Changed constants can be checked at once by the verify mode.

- With the optional extension cable, remote operation is available.

- An LED display operator is available for option.

Easy maintenance and inspection

- Detachable terminals make it easy to exchange units fully wired.

- The one-touch detachable cooling fan life is extended with the on/off control function.

- The accumulated operation time and the cooling fan operation time can be recorded and displayed.

- A support tool using a PC is also available. All constants of each inverter can be managed by a PC.

- The status of output frequency, output current, and input/output terminals can be monitored when trouble has occurred to simplify maintenance work.

Various I/O interfaces

- In addition to analog command input and analog monitor output, it also supports pulse train command input and pulse train monitor output.

- Offers 10 multi-function inputs and 5 multi-function outputs.

- Input terminal logic can be switched to NPN/PNP type. A +24V external power supply is also available for selecting the signal input.

Easy to make exclusive inverter

- The Varispeed G7 lets you make your exclusive inverters with custom software equipping the special functions for your specific machines.

- The rich software library, based on our extensive drive expertise∗, helps you upgrade your equipment.

- ∗ : Crane control, elevator control, energy-saving control (max. motor operation efficiency), PID control, etc.