R1000 - Power Regenerative Unit

R1000 4569 views

The power regenerative unit has braking and regenerative functions that returns load-energy to the power supply.

Use with an AC drive demonstrates superior energy-saving capability in applications with high minus loads such as with cranes and vertical transport lifters.

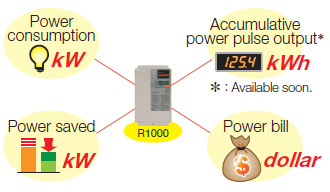

Energy Savings That You Can See

Visualizing Savings in Electricity

You can use analog outputs and communications networks to easily and visually monitor all sorts of data. Operation is as easy as for a Yaskawa 1000-series AC drive.

Reliable and Long Life

Ten Years of Durable Performance

Cooling fans, capacitors, and relays have been carefully selected and designed for a life expectancy of up to ten years.∗

- ∗ : Assumes the drive is running continuously for 24 hours a day at 80% load with an ambient temperature of 40°C.

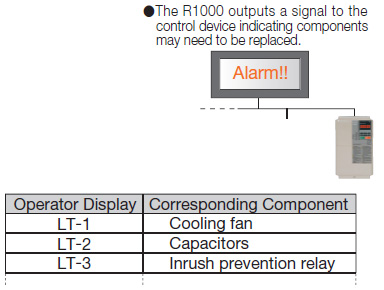

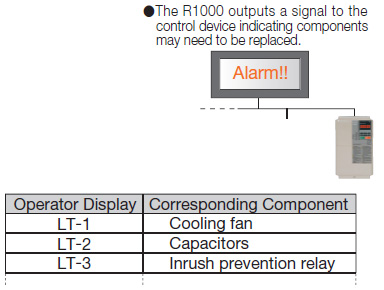

Preventive Maintenance

Performance Life Monitors

The R1000 is equipped with performance life monitors that notify the user of part wear and maintenance periods to prevent problems before they occur.

No Need to Worry Should Problems Occur

Performance Life Monitors

The R1000 is equipped with performance life monitors that notify the user of part wear and maintenance periods to prevent problems before they occur.

No Need to Worry Should Problems Occur

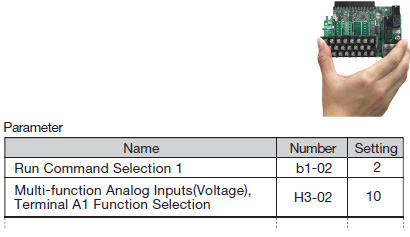

Terminal Board with a Parameter Backup Function

The terminal block's ability to save parameter setting data makes it a breeze to get the application back online in the event of a failure requiring unit replacement.

Easy Support from a PC

Simulation Program for Regeneration Effects

Depreciation simulation gives you an easy way to confirm the cost efficiency of the R1000.

DriveWizard Plus

An indispensable tool for R1000 setup and maintenance.

We Support Global Business

Compliance with Global Standards

Note: Application on pending

Support for Field Networks

RS-422/RS-485 communications capability with the MEMOBUS/Modbus protocol is a standard feature. And you can mount communications options cards to enable using the main open field networks.

*: Available soon

Add the R1000 to save even more energy.

(Conditions)

| Rated Load | : $10/kWh |

| Rated Lifiting speed | : 20 m/min |

| Motor used | : 45 kW, 4 poles, 1,750 min-1 |

| No. of lifting/lowering | : 25 times/h; 109,500/yr |

| (12 h/day for 365 days) | |

| Electricity costs | : $10/kWh |

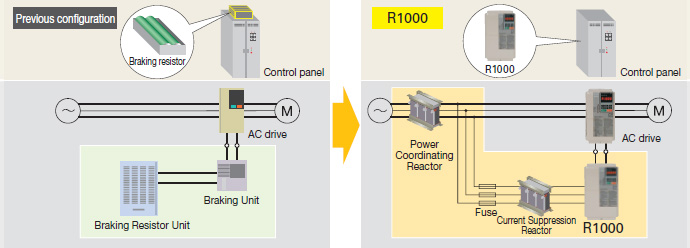

• Replacing Braking Resistors

Increased braking torque provides more braking power with continuous regenerative operation.