Palletizing Package

Palletizing Package 2814 views

Your best fit palletizing solution

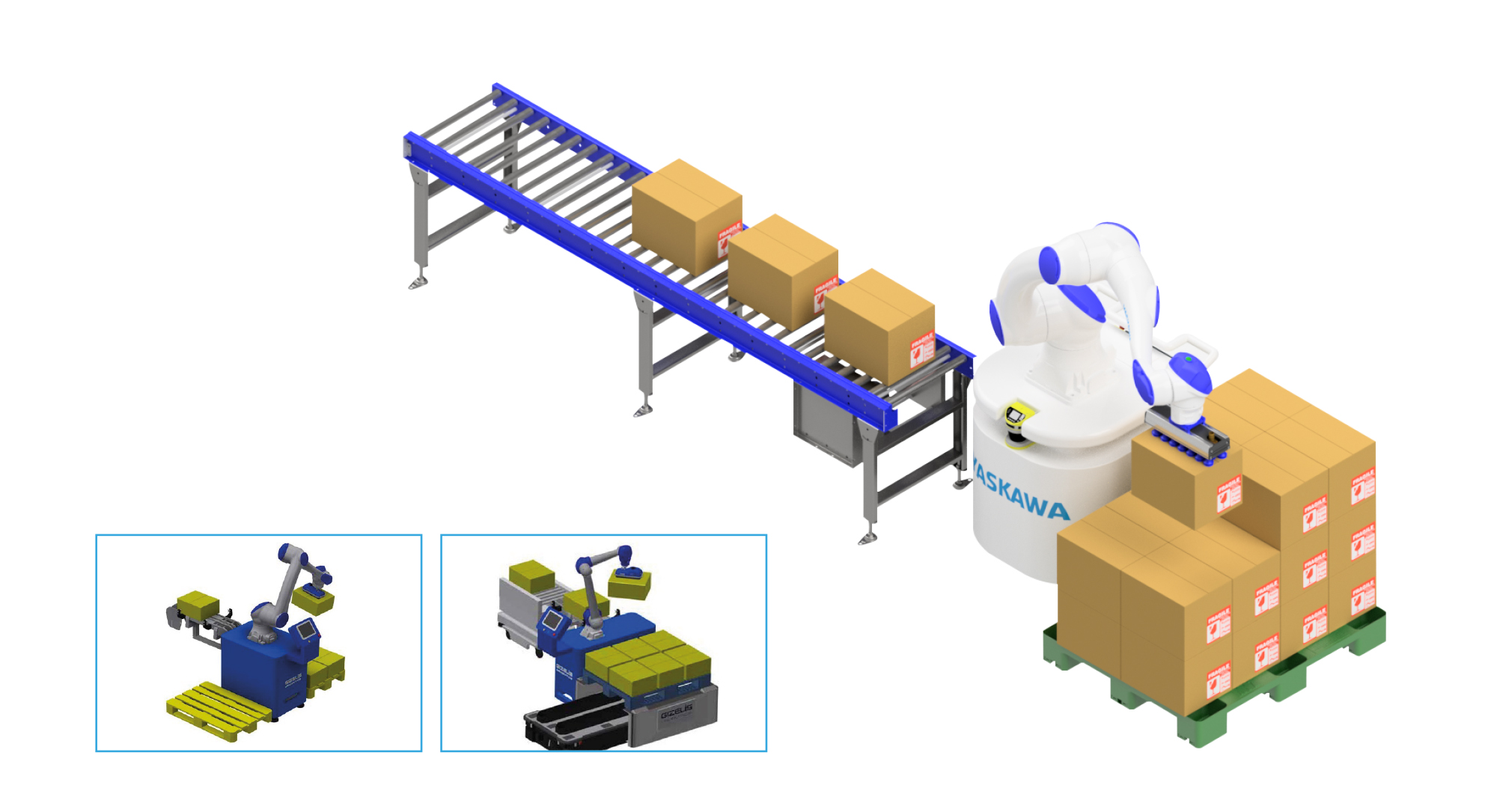

Robotic palletizing provides a modular end of line palletizing system. A flexible solution for palletizing provided in four different configurations. Select the cell that meets your line capacity and requirements. Robotic palletizing cells are ready to improve your line with industrial palletizing robots.

About

Industry Focus

◼️ Food

◼️ Pharmaceuticals

◼️ Chemicals

◼️ Manufacturing

◼️ Small breweries

◼️ Plastic packaging companies

Key Advantages

✔️ User-Friendly

✔️ Cost-Effective

✔️ Advanced reliability

✔️ Small footprint

✔️ Quick start-up cycles

✔️ Low maintenance

Video

Single Palletizer Cells Package

Semi Automation Single Box Palletizer and Stack

Double Palletizer Cells Package

Semi Automation Double Pallet Box Palletizer and Stack

The robot completes one pallet position before switching to the other, allowing time to replace the full pallet. Also, via barcode reader it can build two pallets with different products at the same time.

Application

◼️ Boxes that can be top picked with a vacuum gripper.

Optional Equipment

✔️ Mechanical or electrical gripper

✔️ Parametric programming

✔️ Energy saver

Package

Full Automation Double Pallet Box Palletizer and Stack

Empty pallets are placed initially in a docking station. When needed an empty pallet is picked by the robot and placed at the palletizing location. Full pallets are conveyed automatically out of the safety fence. Optionally interlayer sheets can be placed between the layers of the boxes to increase pallet stability.

Application

◼️ High capacity lines with boxes that can be top picked with a vacuum gripper.

Optional Equipment

✔️ Mechanical or electrical gripper

✔️ Parametric programming

✔️ Energy saver

Cobot Palletizing Package

For Tight Spaces the Collaborative Solution!

✔️ Easily transferred with pallet jack to another line

✔️ Minimum space required

✔️ No guarding required

✔️ Carton box up to 8kg

✔️ Zone safety control

✔️ 1 or 2 palletizing position(s)

✔️ Small to medium productivity capacity

✔️ Plug and play solution

✔️ Human friendly collaborative design

✔️ Easily programmed

✔️ Rigid Steel construction

✔️ Accessible electrical panel

Key Components

✔️ Robot YASKAWA HC20 (Cobot)

✔️ Controller YRC1000 micro

✔️ Collaborative vacuum gripper

✔️ Plastic chain conveyor

✔️ Intuitive HMI

✔️ Compact robot base with integrated electrical panel

Optional Equipment or Features

✔️ Parametric palletizing program

✔️ Smart pendant

✔️ Interlayer handling

✔️ Inspection and rejection (machine vision)

✔️ Mobile Industrial Robot (MiR) docking station for internal logistics