∑-X Series

∑-X Series 4616 views

Digital data solution to accelerate evolution by the ∑-X Series will transport you to the next step in production with the high precision collection and analysis of data.

Shortens takt time

Upgrade to Σ-X for improved production efficiency and further added value from equipment. Also enables faster development and lower production costs.

✔️ Throughput

✔️ Equipment speed performance during development and design

Improved basic performance, essential in accelerated operation

Maximum motor rotation speed

The maximum rotation speed of the motor has increased from the earlier value of 6,000 min-1 to 7,000 min-1.

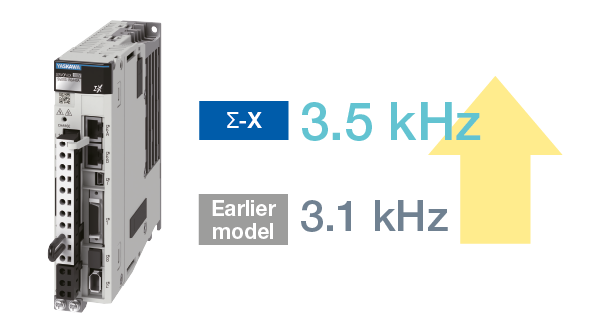

Speed frequency response

Speed frequency response has changed from 3.1 kHz for the earlier model to 3.5 kHz. Maximizing the following performance for the speed reference improves equipment productivity.

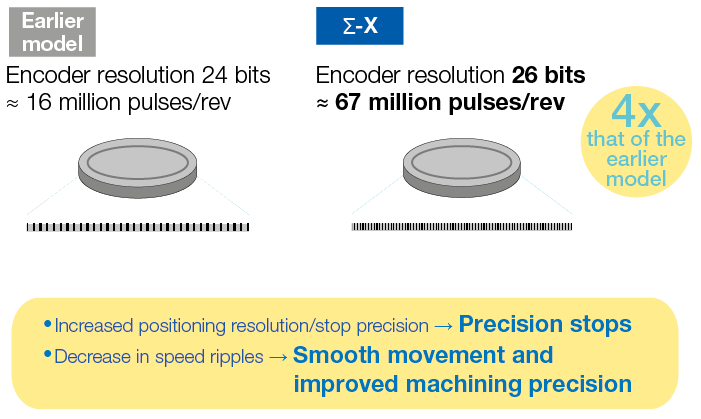

Improves control precision and smoothness

Upgrading to Σ-X reduces inconsistent speed and improves control accuracy. Refinements in smooth movement can enhance machining precision and quality.

✔️ Manufacturing quality

✔️ Equipment precision

✔️ Machining precision in operation

Expanded functions for improved machining precision and quality

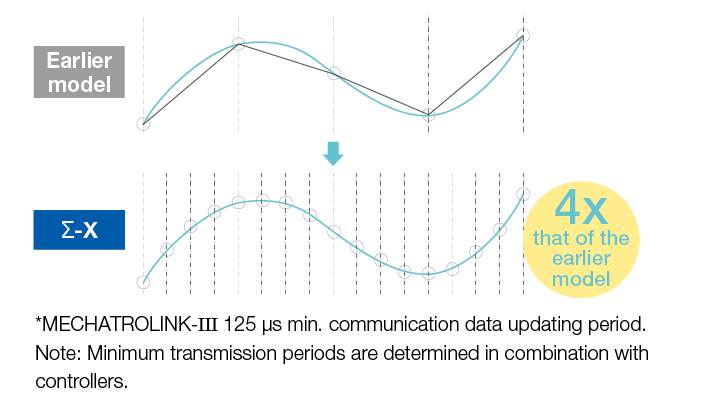

Minimum transmission period of 31.25 μs

(in development) (MECHATROLINK-4 communications)

The minimum period for updating communication data has been changed from 125 μs to 31.25 μs, enabling faster and more fine-grained commands.

Equipped with a high-resolution 26-bit encoder

The resolution of the encoder has been increased to 26 bits, four times that of the earlier model.

∑-X Error Detection Function

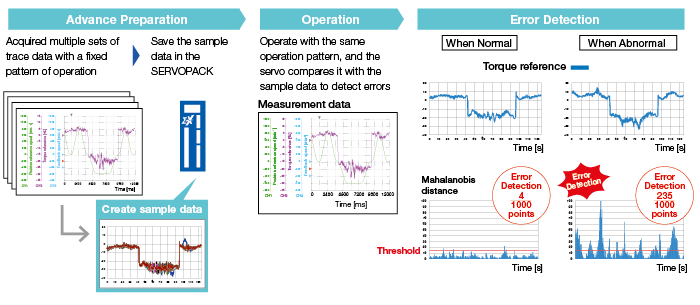

The Σ-X raises the intelligence of the SERVOPACK. Its error detection function detects when equipment is operating in a way that may be "different than normal".

The Σ-X detects equipment errors by comparing sample data stored in the SERVOPACK with operation data. It is useful for detecting equipment errors caused by deterioration over time, judging the quality of products and conrming assembly accuracy.

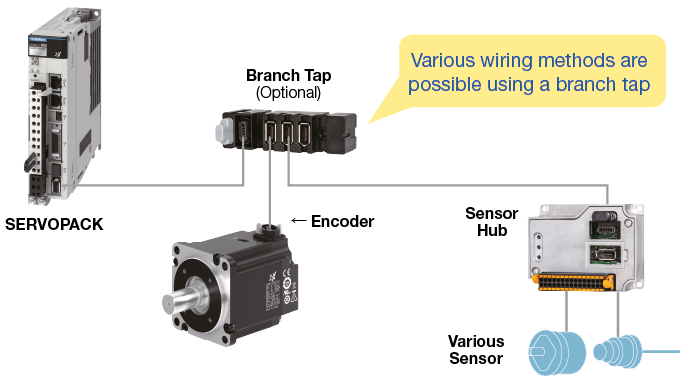

∑-X + ∑-LINK II

Motion and sensor data on the same time axis is collected using Σ-LINK II. Along with reducing the man-hours required for data processing, Σ-X also enables errors to be detected by identifying changes in the equipment.

Features

- Able to connect to multiple commercially-available sensors via a sensor hub

- Able to reduce wiring inside equipment