ProductAug 23, 2022

YASKAWA Electric Corporation (Headquarters: Kitakyushu-city, Fukuoka; Representative Director, Chairman of the Board, President: Hiroshi Ogasawara) announces the launch of a new lineup of MOTOMAN-HC30PL (30 kg payload capacity, 1600 mm reach), a model to palletizing applications such as cardboard, for the human collaboration robot series that has been developed with 10 kg and 20 kg payload capacity.

MOTOMAN-HC30PL

Image for use

In recent years, various industry sectors are promoting automation, quality stabilization, and cost reduction by using robots against the background of the severe labor shortage due to the decreasing working-age population. Amidst this situation, Yaskawa is working on the realization of a space-saving and flexible production line and further expansion of the application field of robots by enhancing the lineup of collaborative robots that can work side by side with workers without a safety fence*1 around the robots.

The newly developed MOTOMAN-HC30PL can handle heavy objects with the same work space as a human by increasing the payload capacity of the human collaboration robot MOTOMAN-HC series to 30 kg.

The features of the series include a high safety level that has been well appreciated by customers and a functionality that allows even first-time users to easily operate the robot. A wide range of end effectors and peripherals sold by hand makers for collaborative robots are also easily interconnected, making it easy to introduce robots.

*1 Safety functions allow the construction of systems without safety fences, but risk assessment and risk reduction measures must be implemented in all cases.

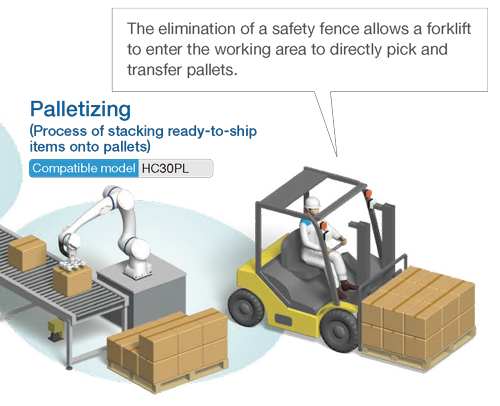

(1) Expansion of application to palletizing by increasing the capacity from 20 kg to 30 kg

When customers ship their final products, large quantities of the products are packed in cardboard boxes, increasing the mass of the boxes themselves. In general, the weight of the carton should be in the range of 10 kg to 20 kg, since manual transfer is required at the destination. However, considering the weight of the hand gripping the carton, a higher weight is required. In addition, cardboard boxes, etc. are stacked on pallets and delivered to logistics departments such as truck transportation in order to improve logistics efficiency. The main pallet size is a square or rectangle with a side of around 1100 mm.

In order to meet these requirements, the product was designed to have a reach of 1600 mm with a payload capacity of 30 kg, enabling use in palletizing applications. Along with the characteristics of the human collaborative robot, which can handle heavy objects in the same working space with a human, the specifications suitable for palletizing realize space-saving equipment. All axes are IP 67 dust- and drip-proof. The surface is coated with acrylic urethane and the tip flange is made of stainless steel. It can also be used for applications that require washing with water for hygienic reasons.

*2 IP indicates the International Protection Code for product dustproofing and waterproofing as specified by the IEC (International Electrotechnical Commission), and in the case of IP 67, dust does not enter and can be protected against temporary submersion.

(2) Realization of easy connection with peripheral devices by Plug & Play kit

The end effector mounting part on the robot tip conforms to the standard “ISO9409-1-50-4-M6”, and can be easily connected and operated with various devices such as end effectors and peripherals that are compliant with the standard. In addition, the ETHERNET cable (Cat. 6), which is convenient for mounting a camera on the robot tip, and I/O cables and air hoses are incorporated as robot built-in cables. By eliminating wiring on the outside of the robot, interference with peripheral devices can be prevented and setup can be easily done.

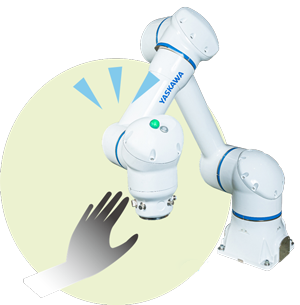

(3) Safe operation and secure design

In keeping with the safety features of the MOTOMAN-HC series, the robot is equipped with a “collaboration mode” that automatically stops when a force exceeding a preset limit is detected from the outside, eliminating the need to install safety fences*1. It is also designed to secure anti-pinching by keeping arm space apart. The automation using robots is possible at sites and processes where the introduction of robots has been postponed to ensure the safety of workers.

▼Safe operation in “collaboration mode”

A robot stops automatically when an external force is applied.

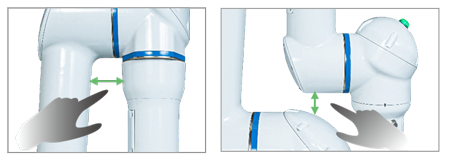

▼Secure design with “anti-pinching”

*The picture of the image is collaborative robot MOTOMAN-HC 20 SDTP.

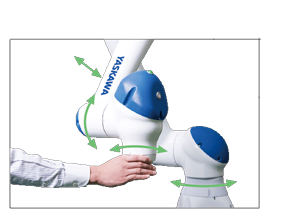

(4) Easy operation even if unfamiliar with robot operation

Besides conventional teaching methods using programming pendants, the robot arm is also equipped with a direct teaching function that allows the robot arm to be gripped by hand and manually manipulated to guide desired movements. Because the robot can be instructed to operate by instinctive operation, it can be easily applied to customers who are unfamiliar with robot operation or processes that require frequent teaching. It also supports the smart pendant, a tablet-type user interface that can be operated instinctively using a touch panel.

▼Smart pendant - Easy operation on touch panel screen

▼Arm can be manually manipulated

*The picture of the image is collaborative robot MOTOMAN-HC 10 DTP.

Packaging, boxed products, and transportation of cardboard packages of them, etc.

*Names mentioned in the above text may be trademarks or registered trademarks of their respective companies.